OEM/ODM China Liquid Silicone Injection Molding Machine - Cold gray Liquid Silicone Rubber parts – JWT Detail:

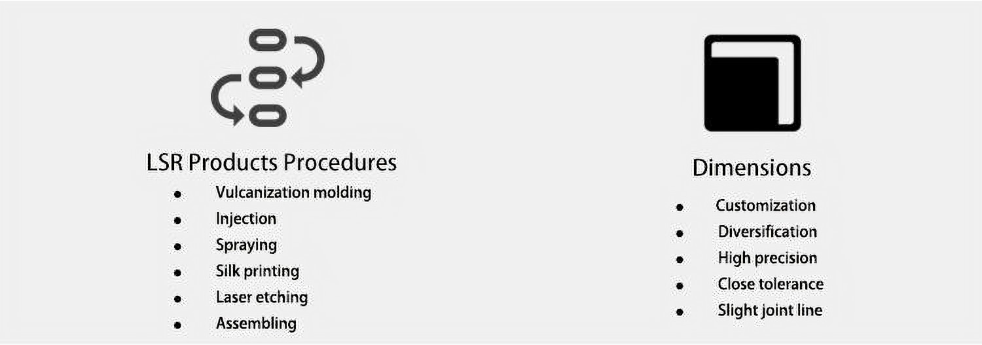

Features Of LSR Products

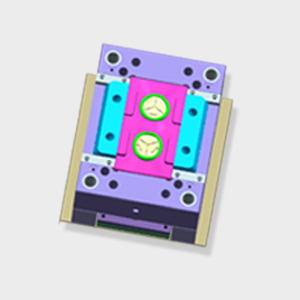

Double Tooling

Zero-Pollution

Precision 0.05mm

High-Volume Production

Quick cycle time

Low Defect Rate

Cost-effective

Higher Automation

Perfect surface & No burr

Material — Liquid Silicone Rubber

LSR is a two-component, platinum (addition/heat) curable and pump-able silicone elastomer that can be molded and cured with very fast cycle times at elevated temperatures

LSR shorter curing cycle time generates higher volume throughput. Highly automatic manufacturing process control minimizes defect risks caused by human factors and guarantees highest level of product uniformity.

LSR can enable short cycle time injection and fully automatic flash-less and trim-free manufacturing.The molding process allows complex part geometry and exact dimensions.

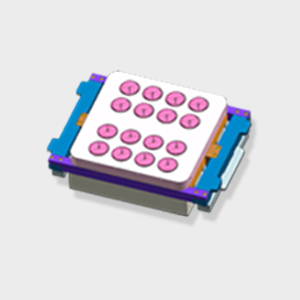

LSR Product Moulding Case

Daily Commodity

![]()

Medical Supplies

Consumer Electronics Accessories

LSR APPLICATIONS

![]()

Aeronautics & Astronautics

![]()

Precision Accessories

Baby Care

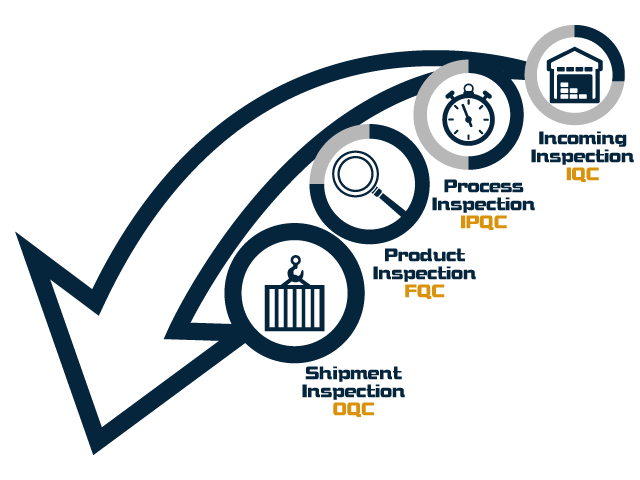

Strict Quality Control — From Start to End

For more information, just click “INQUIRE NOW”

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of OEM/ODM China Liquid Silicone Injection Molding Machine - Cold gray Liquid Silicone Rubber parts – JWT, The product will supply to all over the world, such as: Estonia, Boston, Norway, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, please do not hesitate to contact us.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.